Our Process

Manufacturing of wooden panels (boiserie), structures and built-in furniture.

Wood is at the heart of our furniture. Warm and tactile, it is a natural material that resonates with us on a deep level. We draw on the rich bounty of nature and handle our material with all the love and care it deserves, relying on the infinitely accomplished hands of our artisans to enhance its intrinsic worth. All the wood we source is premium quality because it has to reflect the magnificence of nature and narrate a story – one that expresses all the passion and love we invest in our product.

“Knowledge etched on our hands.

Wood is an age-old noble material, and it is deserving of our respect. The practiced hands of our craftsmen have all the knowledge and experience to bring out the intrinsic worth of wood.”

Далее нужен текст с подробным описанием процесса подбора дерева, сушки, подготовки дерева и технических приемах.

За образец взят текст с сайта производителя кухонь.

Only the choicest raw materials

We only purchase the choicest woods and our master woodworker personally selects the timber batches which are then sent to the production department.

What characteristics do we assess? The boards must already be ‘stabilised’, that is, they must have undergone a drying and seasoning process; we privilege batches deriving from the same log to ensure a uniform flame pattern and tone; to ensure the rigorous quality of our raw materials, we inspect each board to detect any impurities or defects.

Our wood varieties

Not all wood varieties are suitable for building lasting products or for manufacturing kitchen components; the kitchen environment constitutes a stern test for each cabinet, as it must frequently tackle the effects of steam, water and heat; Old Line searches for and selects only the choicest woods such as oak, American walnut, cherry and ash. We make sure that our raw materials derive from processes that respect humans and the environment, and originate from ethically responsible cultivations which do not deplete forests but actually expand their consistency.

We know the wood and process it to last

How do we construct the panels we use to build our kitchens? We take special care in selecting each individual board which we then send to the finger jointing processing phase. This is a delicate phase which can only be carried out manually by a master woodworker familiar with the characteristics and distinctive features of each individual board. The woodworker arranges the boards by counterposing the natural grain patterns to balance the wood’s forces. Wood is a live material and tends to ‘move’, generating imperceptible movements which the counterposed grain patterns and finger jointing cancel out.

We care for each board individually

The boards we purchase are left to ‘rest’ in our warehouses at least for a further 6 months; they are piled by placing slats between the boards so that air can circulate continuously to ensure uniform drying. This is a crucial phase: only those boards with an internal humidity not exceeding 10% and sent to production. This characteristic is among the indispensable requirements for obtaining a stable semi-finished product.

Craftsmanship and technology, together

A special machine engraves the solid wood or creates a finger joint; the various elements are joined and glued together to form continuous slats which are then used to make the panels. This is the so-called ‘finger joint’ which leaves the joints visible on the panel surface.

From the single slat to the panel

The slats are first unframed on all 4 sides then milled laterally; this process allows for slotting one board into the other to achieve an optimal degree of mechanical strength, subsequently enhanced by gluing and pressing the elements together. This process allows for obtaining 350 x 100 cm panels which are then cut into sections, after the calibration cycle which reduces each panel to a thickness of 2 cm.

The panels obtained through this particular process guarantee a greater degree of compactness, stability and mechanical resistance – all essential characteristics of a top-grade product.

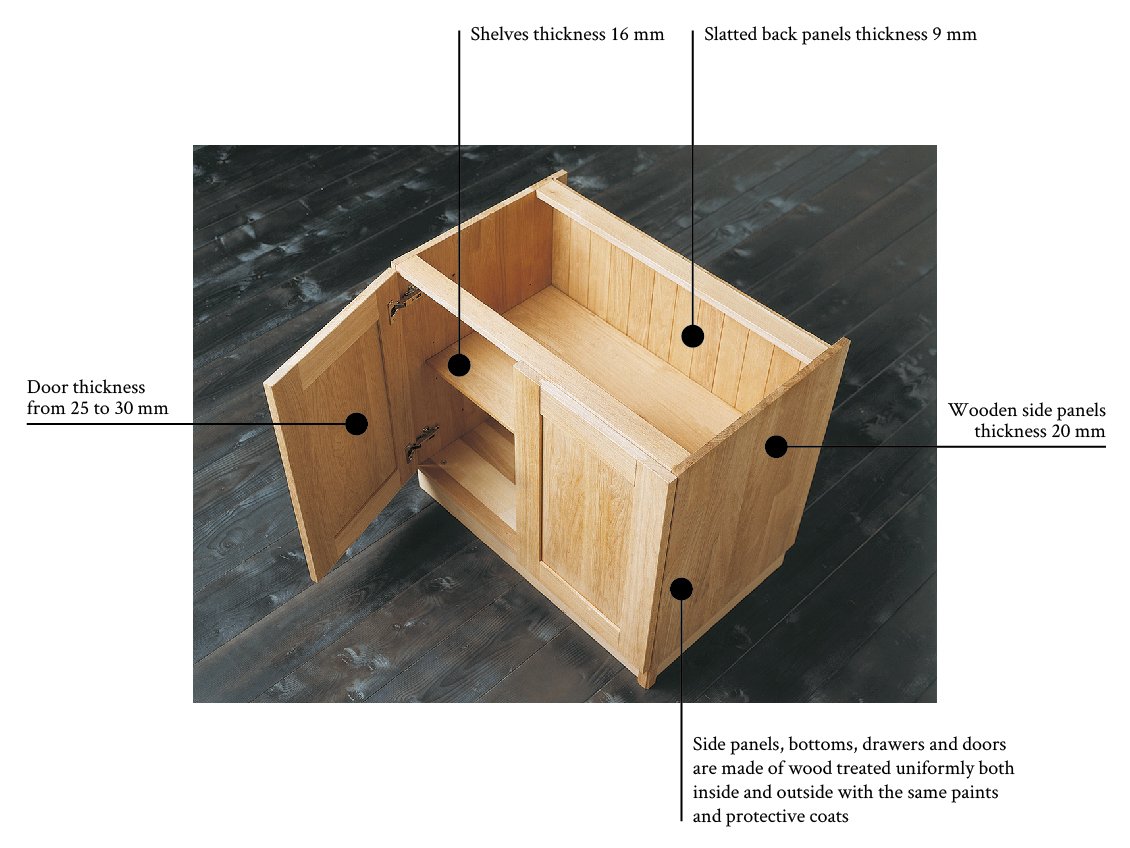

The figures of a sturdy cabinet

All side panels of cabinet carcasses are made of solid wood elements which are 20 mm thick, more than the 18 mm of mass-produced items, and are finger-jointed both vertically and horizontally.

The shelves are made of 16 mm-thick solid wood while the back panels, with their 9 mm-thick solid wood structure, add sturdiness to each model.

The back panels are made with the slatting technique: the slats are milled then their ‘male’ and female’ sections are joined together leaving just under 1 mm clearance on the milled part, to allow for slight adjustments in the wood when it expands due to temperature variations.

Each board is individually identified

We work each kitchen we produce as if it were a single piece, and from this stage onwards each component belongs exclusively to the specific kitchen being produced.

The panel is now ready for being cut into sections of various sizes depending on their intended use; semi-finished elements which will become bottoms, side panels or shelves of base and wall units are filled and smoothed with entirely manual processes.

The drawers

The drawers are entirely made of solid wood and the sides are enhanced by refined hand-crafted dovetailing.

They mount concealed quick-release runners with soft-closing mechanism.

The runners ensure extremely smooth and silent full extraction of the drawer and are tested to withstand 80,000 opening/closing cycles, thus guaranteeing excellent resistance to wear.

ДАЛЕЕ НУЖНА ПРОВЕРКА ТЕКСТА И ПРАВКА.

A detail sparks the project

Ours is a real workshop for bespoke goods where we maintain an uninterrupted dialogue between functionality and aesthetics. Materials and finishes are paired variously with the right units and component parts to deliver outstanding efficiency standards. Each design is made individually, from the design stage right up to the specially selected materials for the final finish. Each product is customised with premier finishes, features and detailing. Ultimately luxury can only stem from a quest for excellence

Before mounting the panels at your home, we pre-mount them in our premises

Each structure is fully pre-mounted dry, to verify its functionality and quality.

We check the dimensions, finishes, shade uniformity and materials; this procedure enables us to guarantee each customer an extremely high degree of precision when assembling the a structure at home.

Manual processing and natural finishes

Pre-finishing

Doors and carcasses are prepared for painting through an initial smoothing phase of the unfinished wood. Subsequently, each surface is sprayed with a lacquered base before undergoing a second manual smoothing process, followed by lacquering in the desired colour. This lengthy and particularly complex process allows for obtaining perfectly smooth surfaces with excellent grip for the lacquer, which is able to withstand scratches and exposure to sunlight.

Paints

We use acrylic and non-toxic paints without formaldehyde, as well as solvent-free water-based paints conforming to EU regulations, in order to safeguard human health and the environment.

Natural finishes

The natural surfaces are finished with oil applied manually and subsequently dabbed with natural fibres; this finish bestows a unique natural effect on the wood because it restores to the material the oil naturally present in wood. Maintenance is straightforward and is effected using detergents formulated with natural waxes; small stains or slightly shaded areas are not defects, but indicate that the product is natural and crafted through traditional processes.

At your home with every care

We take special care in packaging your timber structures so that you receive them as they were originally manufactured. Besides safeguarding the integrity of our structures, we also protect the environment by using only 100% divisible and recyclable materials for packaging purposes.

Together with your panels even after years

We are high-end artisans and are accustomed to guaranteeing – even after several years – the availability and reproducibility of our wooden structures. There’s no need to worry, as we can replace your damaged door or complete the structure with new modules or create a new area matching the existing style and materials. We work on a project basis and develop tailored solutions with customised features thanks to the artisan expertise of our master woodworkers.

Craftsmanship

Designing a space is like tailoring a suit: what counts is not only the product itself, but what it stands for and the creation of a lifestyle. We blends its cabinet making heritage, ability to manufacture custom products and craftsmanship with latest generation machinery and production technologies; only such a combination can yield genuine luxury. We are a company in where artisan values are applied to international projects on an industrial scale, entirely custom-made.

100% Made In Italy

Genuine Italian craftsmanship

Our production rigorously complies with the highest standards, according to genuine Italian craftsmanship criteria. From the raw material selection phase down to the quality of the production process, effected by highly qualified personnel, we oversee every single detail to ensure that our product reflect the quality and design of an impeccable furnishing element.

Italian design service

We customise each product

We design furnishing solutions in which beauty and functionality combine harmoniously to create a durable designs. We offer a range of unique services with regard to flexibility, materials research, refined processing and customised details for each project.